The floating mortise and tenon joint is a cornerstone technique in woodworking that has been refined over centuries. It combines both strength and flexibility, making it a preferred choice for furniture makers, cabinet builders, and joinery professionals. Unlike a traditional fixed mortise and tenon, the floating variant allows for slight movement, which can be crucial in accommodating seasonal wood expansion and contraction. Its versatility makes it ideal for large panels, frame-and-panel doors, and custom joinery projects where precision and durability are essential.

Understanding Floating Mortise and Tenon Joints

A floating mortise and tenon is a type of woodworking joint where the tenon is not permanently glued into the mortise. Instead, it floats within the mortise cavity, allowing slight movement along the wood grain. This design is particularly useful in applications where wood panels are exposed to changes in humidity or temperature, as it helps prevent warping, splitting, or cracking. The joint provides mechanical strength while maintaining some flexibility, which traditional fixed joints cannot achieve.

Components of the Floating Mortise and Tenon

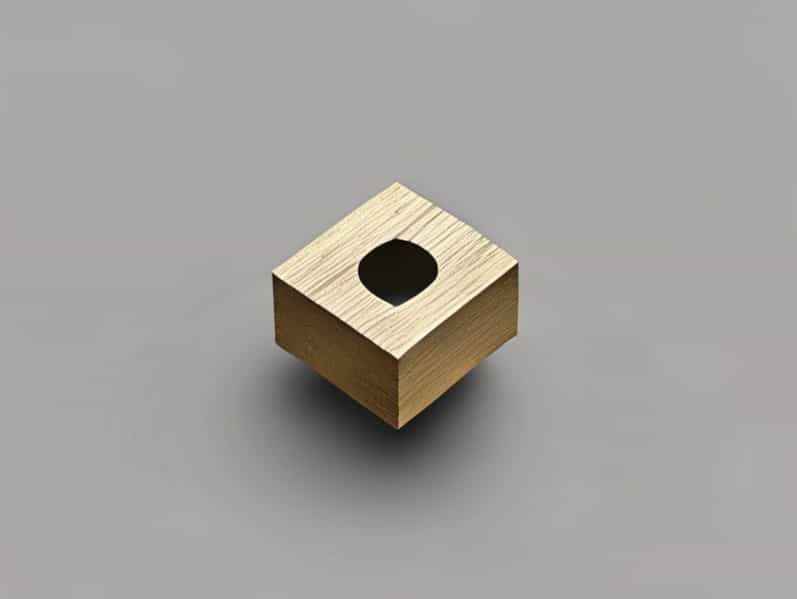

Like all mortise and tenon joints, the floating variant consists of two primary components the mortise and the tenon.

- MortiseA rectangular or square cavity cut into one piece of wood. It must be precise in depth and width to fit the tenon securely while allowing minimal movement.

- TenonA projecting piece on the end of another wood component, designed to fit snugly into the mortise. In floating joints, the tenon is slightly smaller than the mortise cavity, enabling it to move freely within a controlled range.

Precision in crafting both components is essential for achieving the desired balance between strength and flexibility. The tenon must be durable enough to bear structural loads while allowing the slight movement needed to accommodate natural wood expansion.

Applications of Floating Mortise and Tenon Joints

Floating mortise and tenon joints are widely used in various woodworking applications. Their unique properties make them suitable for both functional and aesthetic purposes, particularly in projects that require durable yet flexible joinery.

Frame and Panel Doors

One of the most common applications is in frame and panel doors. The floating tenon allows the central panel to expand and contract without causing stress on the surrounding frame. This flexibility prevents splitting or warping of the frame over time, especially in solid wood doors exposed to seasonal humidity changes.

Furniture Construction

High-quality furniture often relies on floating mortise and tenon joints for structural integrity. Tables, chairs, and cabinets benefit from the joint’s ability to maintain stability while allowing slight movement. Floating tenons help absorb stress, reducing the likelihood of joints loosening or furniture wobbling after years of use.

Custom Woodworking Projects

Cabinetmakers and custom woodworkers use floating mortise and tenon joints for complex assemblies such as bookcases, sideboards, and modular furniture. The joint’s combination of strength and flexibility ensures that large panels or frames remain aligned and durable, even under varying environmental conditions.

Advantages of Floating Mortise and Tenon Joints

The floating mortise and tenon offers several advantages over traditional fixed joints, particularly in modern woodworking and fine furniture making.

Accommodates Wood Movement

One of the most significant benefits is its ability to accommodate seasonal wood movement. Wood naturally expands and contracts with changes in humidity, and a rigid joint can lead to cracking or warping. The floating tenon moves within the mortise, reducing stress on the surrounding wood and extending the life of the project.

Increased Strength and Stability

Despite its flexibility, a properly crafted floating mortise and tenon joint is extremely strong. It provides mechanical interlocking between components, distributing loads evenly and preventing joint failure. This makes it suitable for both lightweight and heavy-duty furniture applications.

Ease of Assembly

Floating mortise and tenon joints can simplify assembly in certain woodworking projects. Because the tenon is pre-made and not glued into the mortise, it allows for easier alignment of panels and frames during construction. This is particularly advantageous when dealing with large or heavy components that require precise positioning.

Aesthetic Appeal

In addition to functional benefits, floating mortise and tenon joints offer aesthetic advantages. They can be designed to be invisible, leaving clean lines and smooth surfaces without exposed joinery. This is ideal for fine furniture and cabinetry where the visual appearance of the joint is as important as its structural function.

Techniques for Creating Floating Mortise and Tenon Joints

Creating a precise floating mortise and tenon requires careful planning, accurate measurements, and the right tools. Woodworkers often use a combination of hand tools and power tools to achieve optimal results.

Cutting the Mortise

The mortise must be clean, square, and deep enough to house the floating tenon. Common methods include

- Chisel and MalletTraditional hand tools allow for precise control and smooth cavity walls.

- Mortising MachinePower tools can speed up the process and ensure uniform mortises, especially for repetitive tasks.

- RouterA router with a straight bit can create accurate mortises, particularly for wider panels.

Shaping the Tenon

The tenon must fit within the mortise with slight clearance to allow movement. Techniques include

- Table SawCommonly used for cutting straight, uniform tenons on multiple pieces.

- Router with Tenon JigEnsures precise tenon dimensions and repeatable results for large batches.

- Hand Planes and ChiselsAllow for fine adjustments and perfect fit.

Assembly Considerations

When assembling floating mortise and tenon joints, care must be taken to align the pieces correctly. Glue is often used selectively on parts of the joint that do not restrict the floating tenon’s movement. Clamps may be applied to hold components in place while ensuring the tenon retains the desired flexibility. Proper sanding and finishing ensure smooth operation and long-term durability.

Challenges and Tips

While floating mortise and tenon joints offer many benefits, they also come with challenges that woodworkers should consider.

- Precision RequiredThe mortise and tenon must be accurately cut to ensure proper fit and function.

- Material SelectionChoosing wood that responds well to movement and stress is essential for long-lasting joints.

- Tool MasteryAchieving clean, square mortises and perfectly sized tenons requires skill and practice.

- Glue StrategyApplying glue in the wrong place can restrict movement and negate the benefits of a floating tenon.

Woodworkers often practice on scrap pieces before attempting critical joints to ensure precision and reduce errors.

The floating mortise and tenon joint is a versatile, durable, and elegant solution in woodworking. Its ability to combine strength with flexibility makes it ideal for doors, panels, furniture, and custom projects where wood movement and long-term stability are concerns. Mastering this joint requires skill, attention to detail, and understanding of wood behavior, but the results are highly rewarding. Whether for traditional woodworking or modern furniture design, the floating mortise and tenon remains a critical technique for achieving both functional and aesthetic excellence.