Linear polymerization of ethyne, commonly known as acetylene, is a fascinating process in the field of organic and polymer chemistry. This chemical transformation allows for the production of long-chain hydrocarbons from a simple two-carbon molecule. Ethyne, a highly reactive alkyne, serves as a valuable monomer in the synthesis of conjugated polymers. The formation of linear polymers from ethyne involves specific reaction conditions and catalysts that guide the monomer units into organized, repeating structures. This process is not only scientifically significant but also has practical applications in the production of advanced materials with desirable electrical and mechanical properties.

Understanding Ethyne as a Monomer

Ethyne (C2H2) is the simplest alkyne, characterized by a triple bond between two carbon atoms. This triple bond makes ethyne highly reactive and suitable for polymerization. In its gaseous state, ethyne is colorless and flammable, with a distinct odor. Its reactivity primarily arises from the high electron density within the triple bond, which can be broken under the right conditions to allow bonding with other ethyne molecules.

Key Properties of Ethyne

- Molecular formula: C2H2

- Linear geometry due to sp-hybridized carbon atoms

- High reactivity due to Ï-bonds in the triple bond

- Potential to form extended conjugated systems upon polymerization

Mechanism of Linear Polymerization

Linear polymerization of ethyne typically involves the breaking of Ï-bonds in the triple bond and the formation of Ï-bonds between carbon atoms of adjacent monomers. The result is a long, conjugated polymer chain known as polyacetylene. There are several methods to initiate this reaction, but the most common involve catalysts that help control the reactivity and alignment of the monomers.

Initiation of Polymerization

The polymerization begins when the triple bond in ethyne is activated by a catalyst or an initiator. This can be achieved through:

- Free-radical initiation

- Anionic or cationic mechanisms

- Transition metal catalysts, such as ZieglerNatta-type systems

Propagation

Once initiation has occurred, the active site on one ethyne molecule reacts with the next, forming a bond and creating a new active site. This process repeats, extending the polymer chain linearly:

- Each step forms a new bond between carbon atoms

- Ï-electrons from the triple bond shift to accommodate bonding

- The backbone of the polymer becomes a conjugated system of alternating single and double bonds

Termination

Polymerization is terminated by a variety of mechanisms, such as combination, disproportionation, or reaction with a terminating agent. The resulting polymer depends on how the chain is capped and the reaction conditions used.

Structure and Properties of Polyacetylene

The most well-known product of ethyne polymerization is polyacetylene, a linear conjugated polymer. Its unique structure gives rise to intriguing electrical and optical properties. The backbone of polyacetylene consists of alternating single and double bonds, making it a semiconductor in its undoped form and a conductor when doped with appropriate substances.

Structural Features

- Linear chains with repeating -CH=CH- units

- Planar geometry allows for Ï-orbital overlap

- Delocalization of electrons along the chain

Physical and Electrical Properties

- Low crystallinity but high flexibility

- Semi-conductive in pure form

- Electrical conductivity increases dramatically upon doping

- Black or dark brown in appearance due to light absorption

Applications of Linear Polyethyne

The polymerization of ethyne into linear chains like polyacetylene has opened up many possibilities in the field of conductive polymers. Although polyacetylene itself is unstable in air and moisture, its discovery inspired the development of many more stable and functional conductive polymers.

Technological Uses

- Flexible electronics

- Antistatic coatings

- Organic solar cells

- Light-emitting diodes (LEDs)

- Electrochromic devices

Scientific Importance

Polyacetylene played a critical role in the development of organic electronics and earned its discoverers the Nobel Prize in Chemistry in 2000. It demonstrated that organic compounds could exhibit electrical conductivity, challenging the traditional division between conductors and insulators.

Challenges in Ethyne Polymerization

Despite its potential, the linear polymerization of ethyne presents several challenges. Ethyne is a gas under normal conditions, making it difficult to handle. Moreover, the resulting polymer, polyacetylene, is sensitive to oxygen and moisture, which limits its practical use unless properly protected or modified.

Stability Issues

- Polyacetylene is prone to degradation in air

- Requires doping and encapsulation for real-world applications

- High reactivity of ethyne can lead to side reactions

Control of Polymer Structure

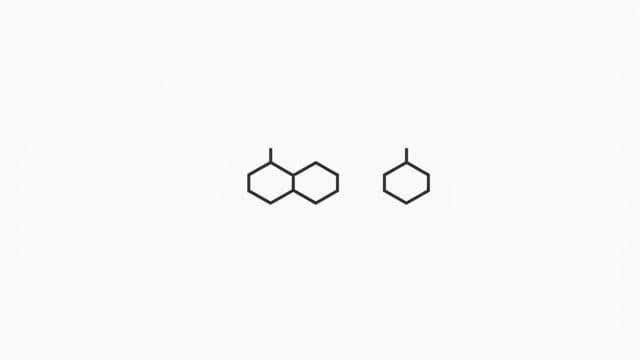

Achieving a uniform, linear polymer chain can be difficult. Factors such as catalyst choice, temperature, and pressure must be tightly controlled to ensure consistent polymer growth. Improper conditions may lead to branching or cross-linking, which alters the properties of the final material.

Alternative Routes and Derivatives

To overcome some of the drawbacks of polyacetylene, researchers have developed alternative derivatives and copolymers. These materials retain the desirable properties of polyacetylene while improving stability and processability.

Examples of Modified Polymers

- Substituted polyacetylenes with functional side groups

- Block copolymers with more stable polymer segments

- Incorporation of polyacetylene into composite materials

These modifications help enhance the environmental resistance of the polymer and make it more compatible with manufacturing techniques such as spin-coating and printing.

Environmental and Safety Considerations

As with any chemical process, the polymerization of ethyne must consider environmental and safety concerns. Ethyne is highly flammable and can form explosive mixtures with air. Proper ventilation, controlled environments, and trained personnel are essential for safe polymerization operations.

Sustainable Development

Researchers are also exploring green chemistry approaches to polymerize ethyne using renewable catalysts and eco-friendly solvents. Such innovations aim to reduce the environmental footprint of polymer production and broaden its appeal for industrial applications.

Linear polymerization of ethyne is a chemically intriguing and technologically relevant process. From its basic chemistry to its potential in advanced electronics, the transformation of a simple alkyne into a conductive polymer illustrates the power of molecular design. While challenges remain, ongoing research continues to expand the possibilities for linear ethyne-based polymers in the fields of materials science, electronics, and sustainability. Understanding the principles behind this process is essential for anyone interested in polymer chemistry, advanced materials, or the future of organic electronics.